Several key factors influence the boring precision of any line boring machine. Machine rigidity, spindle runout, feed system stability, cutting tool quality, and environmental vibration all play major roles. Poor alignment during setup can cause ovality exceeding 0.05 mm, while insufficient bar stiffness leads to chatter marks that compromise bearing life in rudder stocks and stern tubes.

The boring bar is the heart of every portable line boring machine. Its manufacturing process begins with high-grade alloy steel forgings, followed by precision CNC turning, stress-relief heat treatment, and final cylindrical grinding. Leading manufacturers demand roundness error within 0.03 mm and straightness better than 0.01 mm per meter. When choosing a high-precision boring bar for in line boring machine applications, insist on third-party inspection reports, verify surface hardness (HRC 58–62), and confirm chrome plating or nitride treatment for corrosion resistance in marine environments. Avoid bars with visible seams or inconsistent diameters—these directly degrade stern tube shaft hole line boring results.

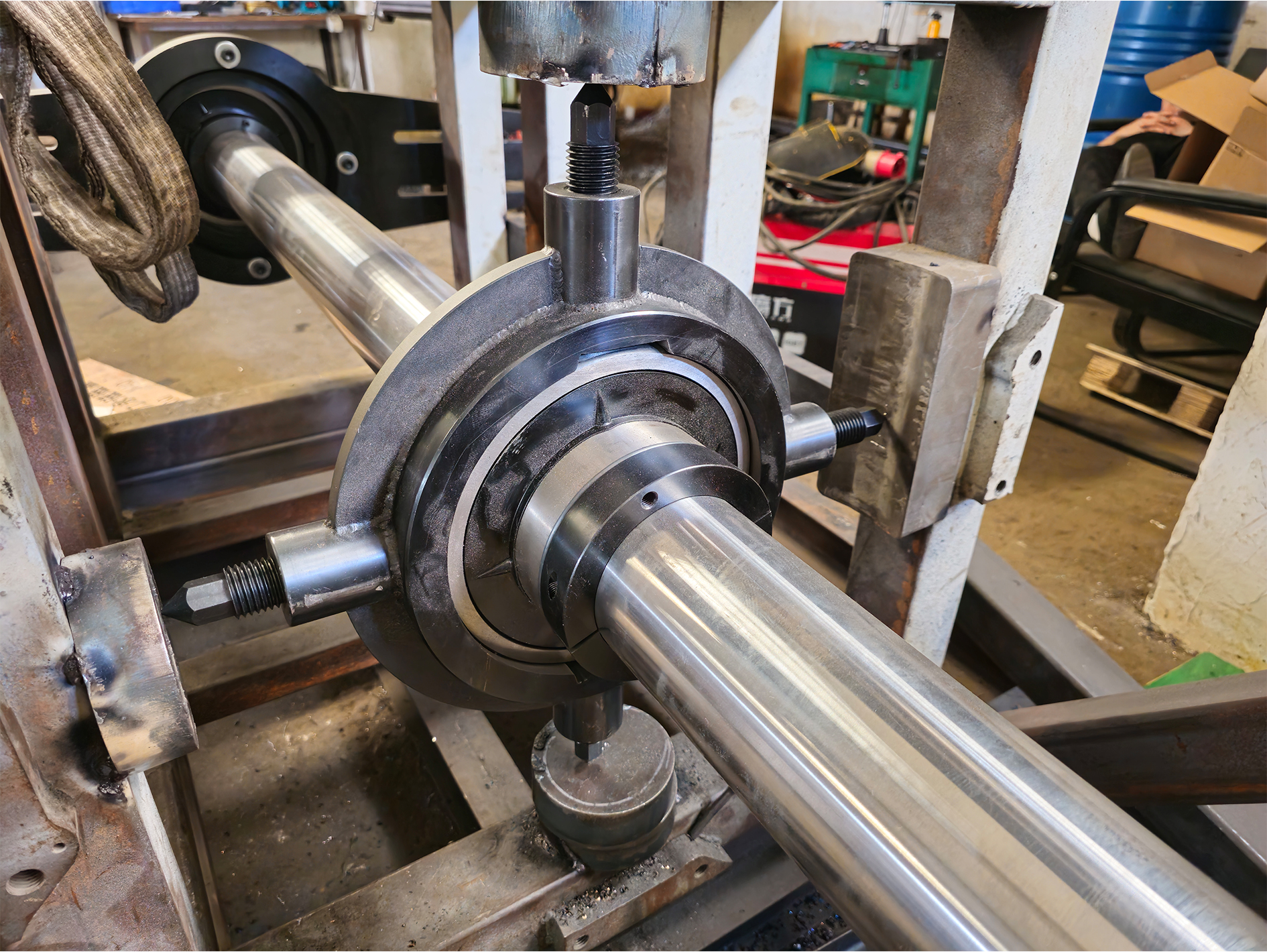

Equally important are the support bearings. High-precision bearings in a portable line boring machine must feature pre-loaded roller or ball designs with radial runout under 0.005 mm. Select bearings certified to ABEC-7 or P4 standards, equipped with labyrinth seals to resist saltwater ingress. Proper bearing clearance adjustment ensures the entire in situ line boring machine system maintains concentricity throughout long bores typical of ship rudder and stern shaft work.Compared with heavy-duty workshop boring mills, on site boring machine solutions offer decisive advantages. Portable line boring machine systems can be transported directly to the vessel, eliminating the need to remove massive stern tubes or rudder stocks. Setup time drops from days to hours, and ship rudder on site boring or stern tube shaft hole line boring can be completed while the ship remains in service or alongside the quay—dramatically cutting dry-dock costs.

Zhengzhou Portable Tools Co.,Ltd stands out by strictly controlling every stage—design, production, manufacturing, assembly, and on-site processing precision. The company’s portable line boring machine and line boring machine series guarantee boring bar roundness error within 0.03 mm through full-process CNC machining and laser-verified quality checks. Whether your project requires in line boring machine capability for 300–1500 mm diameters or specialized in situ line boring machine configurations, Zhengzhou Portable Tools delivers proven reliability for stern tube shaft hole line boring and ship rudder on site boring worldwide.

By evaluating these technical factors and partnering with a manufacturer that obsesses over precision like Zhengzhou Portable Tools Co.,Ltd, ship operators achieve faster, safer, and more cost-effective repairs.