How to Produce the Reliable Portable Flange Milling Machine

In the realm of industrial machining, the portable flange milling machine stands out as a versatile and essential tool. Also known as an on site milling machine, circular milling machine, in situ flange milling machine, or simply portable milling machine, this equipment is designed for precision milling of flanges directly at the job site. Unlike traditional stationary mills, it allows for on-the-spot repairs and modifications without the need to disassemble large components, saving time and reducing downtime in critical operations.Why use a portable flange milling machine?

The primary reason is its unparalleled convenience and efficiency. Traditional methods often require transporting heavy flanges to a workshop, which can be costly and logistically challenging. In contrast, this portable solution brings the milling capability to the flange, ensuring minimal disruption. Its advantages include high portability, thanks to lightweight designs and easy setup; exceptional precision for achieving tight tolerances; and versatility in handling various flange sizes and materials.

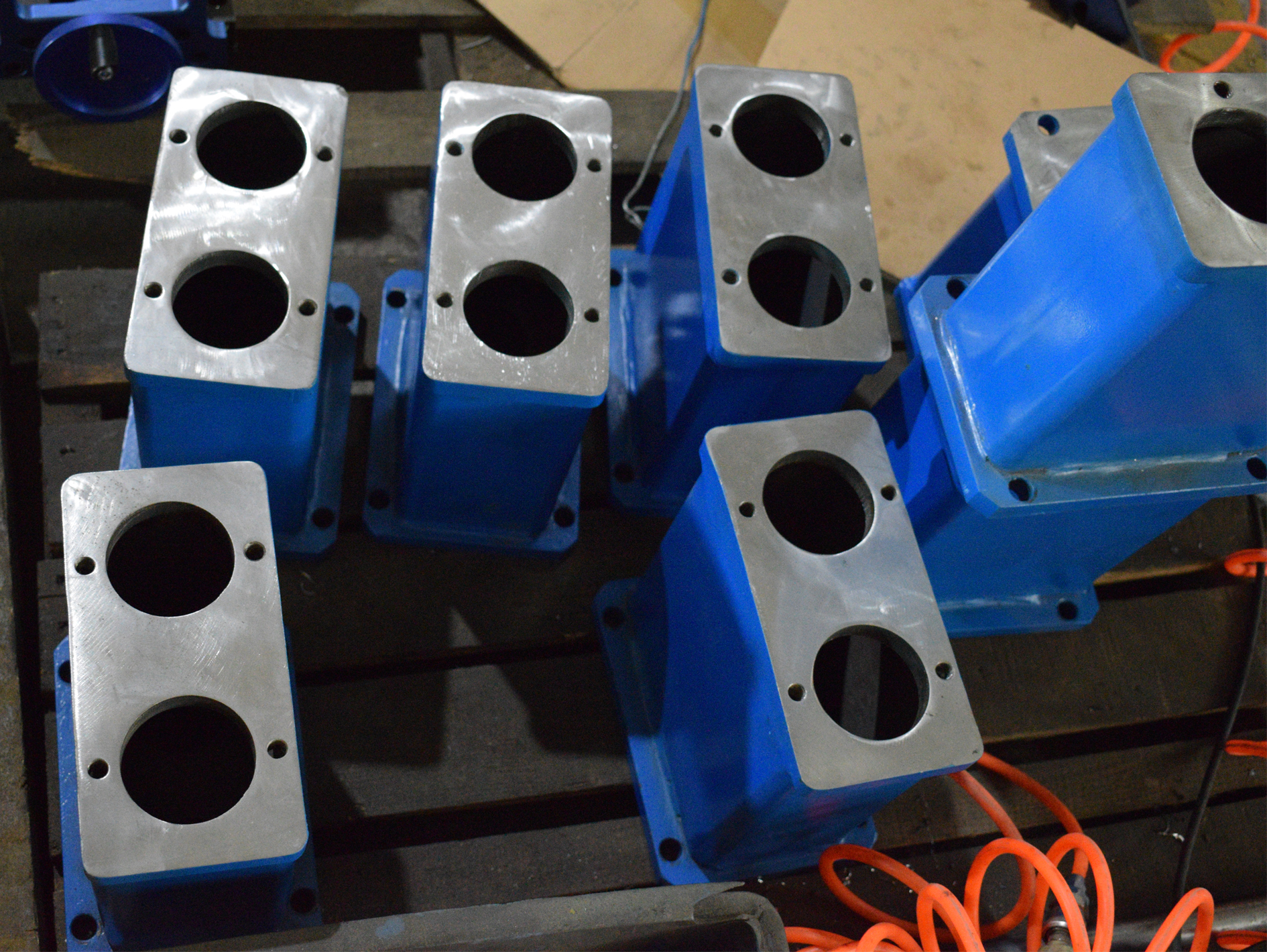

The support arm of IFF3500 flange milling machine will be machined with grinder carefully before mounting.

This machine excels in maintaining seal integrity, preventing leaks in high-pressure systems, and extending the lifespan of industrial equipment.Portable flange milling machines find applications across diverse industries. In petrochemical plants, they are used for repairing pipeline flanges to ensure safe operations. Ship repair and maintenance benefit from their ability to mill marine flanges without dry-docking vessels. Offshore drilling platforms rely on them for on-site processing of large flange sealing surfaces amid harsh marine environments. They are ideal for wind turbine base machining and repairs, where accessibility is limited. In hydropower, thermal power, and nuclear power stations, these machines handle base processing and maintenance, ensuring structural integrity under extreme conditions.

The mounting base will be machined by our flange facing machine to ensure the surface roughness.

Additionally, they serve in various annular flange sealing face environments, such as aerospace, mining, and heavy machinery, where precision on-site milling is crucial for safety and performance.How to use a portable flange milling machine? Start by assessing the flange condition and selecting the appropriate tool size. Secure the machine to the flange using mounting clamps or magnetic bases for stability. Align the milling head with the surface, set the desired depth and speed via the control system, and initiate the milling process. Monitor progress with integrated sensors for accuracy, and perform multiple passes if needed for a smooth finish.

Always follow safety protocols, including wearing protective gear and ensuring the work area is clear.

Zhengzhou Portable Tools Co., Ltd, we are a leading domestic manufacturer of portable on-site machining equipment. Our engineers boast over 20 years of design and field processing experience, tailoring solutions from the design phase based on real-world job site conditions. We control every production detail for superior quality, utilizing CNC five-axis machining centers and top international components like Japan’s Mitsubishi systems, NGK high-precision bearings, THK high-precision ball screws, and Sweden’s Schneider Electric for unmatched reliability.

Our goal is to provide customized, reliable, high-precision products for clients. We welcome custom drawings, ODM/OEM services, and tailored production solutions for your on-site machining needs.