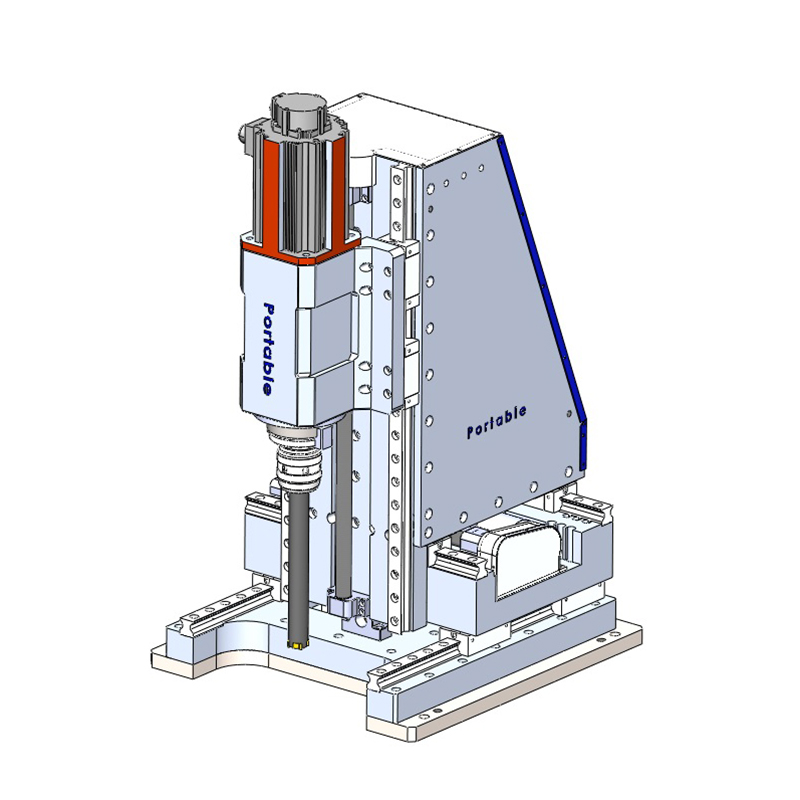

Factory Cheap Hot Flange Machining Tool - IFF1000 Flange Facing Machine – Portable Tools

Factory Cheap Hot Flange Machining Tool - IFF1000 Flange Facing Machine – Portable Tools Detail:

Detail

Li Xun Bo Trading provides a variety of flange facing machine tools for resurfacing flat face and raised flange faces ,RTJ grooves for ring type joint gaskets. Portable flange facing machines provide a continuous groove spiral serrated finish,it’s very essential for achieving leak-free connections on many types of flange joint and reconditioning flange gasket seating area’s perfect.

The rigid and versatile IFF1000 delivers high-torque performance to quickly re-face flanges and repair sealing and bearing surfaces efficiently and cost-effectively

Powered 360° tool post – for a wider range of machining operations

6 continuous groove facing feeds for a gramophone finish

Quick set adjustable clamping jaws, minimize set up time

Most of our flange facing machine configured for face machining, reface, mill, O-ring groove, RTJ grooves, counter bore, OD chamfer, chamfer of counter bore.

Benefits: Exceedingly versatile, Highly portable, Latest linear technology, High efficiency, Low noise ,level 2.0hp drive ,Storage/shipping box

Optional drive power

IFF1000 portable facing tools , an internally mounted and robust flange facing machine capable of producing 6 different continuous groove gramophone finishes to ASME Standard.

Powerful Torque

IFF1000 Flange facing machine tools delivers high-torque performance to quickly re-surface flanges and repair sealing and bearing surfaces efficiently and cost-effectively.

Portable flange facing machine futures

Precision construction

Geared continuous groove facing feeds for a gramophone finish (ASME Standard)

Striker/kick boring feeds, to complete a full range of machining applications

Quick set independent base for improved on-site operation

Hardened slide ways to maintain long term accuracy

Swivel tool post for groove details; reduces need for separate accessories

Applications

Dongguan Portable Flange Facers are suitable:

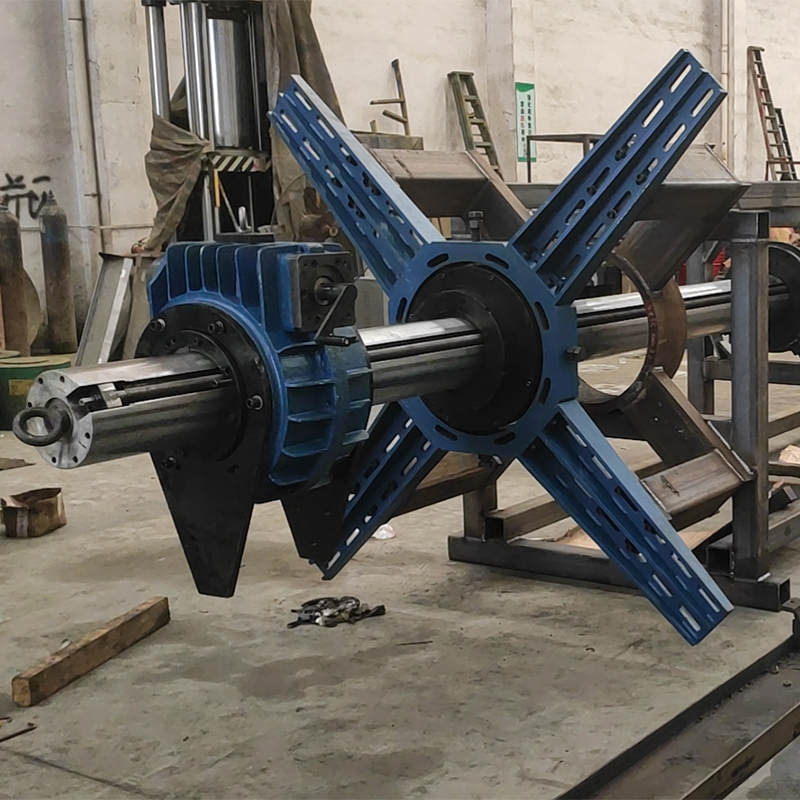

Gasket seal on tube sheet machining

Drilling, milling, and mount facing of ship thruster

Power plants station,

Chemical plants,

Oil&gas industries,

Flange faces on piping systems

Pump housing flanges

Weld preps

Tube sheet bundles.

Bearing mounting bases

Final drive hubs

Bull gear faces

Manufacturing of mining

ID mounted flange facer IFF1000 is prepared to implement applications complying with ASME standards.

IFF1000 flange facing tools allows for a high quality machining, resulting in one continuous groove producing a true gramophone finish.

ID mount flange facing working on the flange type face below:

Flat Face

Raised Face

Ring Type Joints (RTJ) groove

Tongue & Groove

Lens Ring

Grayloc® (hub profile)

Compact Flanges

O ring

Chamfer

Counter bore

Chamfer counter bore

Customized portable flange facing machine is welcomed.

Product detail pictures:

Related Product Guide:

We always continually offer you conscientious purchaser services, and the widest variety of designs and styles with high quality materials. These efforts include the availability of customized designs with speed and dispatch for Factory Cheap Hot Flange Machining Tool - IFF1000 Flange Facing Machine – Portable Tools , The product will supply to all over the world, such as: Benin, India, Serbia, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.