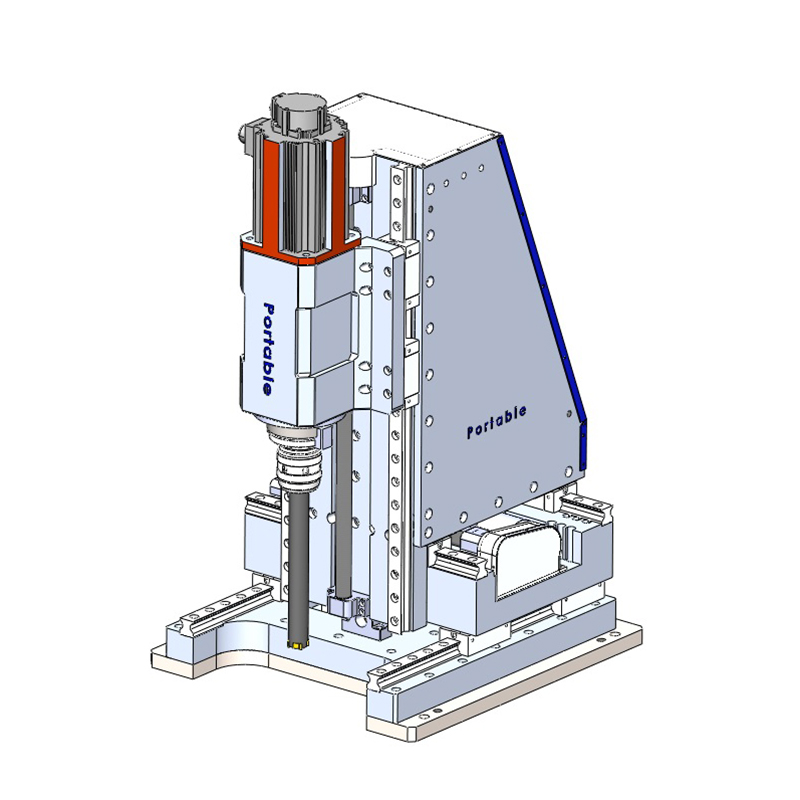

Hot New Products In Line Boring - LBM220 Portable Line Boring Machine – Portable Tools

Hot New Products In Line Boring - LBM220 Portable Line Boring Machine – Portable Tools Detail:

Detail

Heavy duty on site line boring machine LBM220, boring diameter: 600-1500mm, boring bar could reach to 12 meters . One reliable line boring machine for on site service.

Heavy duty line boring machine boring diameter could be arranged to 1500mm. Automatic or semi-automatic on site line boring system are available to designed.

On site heavy duty line boring machine is equipped with two-axis or three-axis linkage CNC system, and the system can choose Guangzhou CNC, Huazhong CNC, Fanuc system, or Siemens cnc system.

Heavy duty cnc on site line boring machine could bore straight holes, tapered holes, spherical holes, or other geometric curve holes;

CNC line boring Machine configuration automatic installation, calibration and automatic processing, automatic detection system;

The sealed lubrication system allows the on site line boring machine to be installed horizontally, vertically or upside down;

The cnc line boring machine is equipped with heavy-duty self-aligning spherical bearings without clearance, which makes the machine easy to install, run smoothly and without vibration;

The upper and lower bearings are self-aligned and locked by automatic locking screws evenly distributed around the circumference, and the locking screws are respectively driven by servo motors;

The overall structure is light, the horsepower is large, the installation is convenient, and the constant torque between each speed is stepless speed regulation.

The cutting force is pretty strong, and the cutting depth can reach 5mm during rough machining; the machining accuracy is high. Surface roughness can reach Ra1.6 during finishing

LBM220 in field heavy duty line boring machine boring stroke same as the length of boring bar, the lead screw inside the boring bar which ensure the boring depth longer enough for the on site line boring jobs.

LBM220 on site line boring machine has different power for it’s options. Servo motor with 7.5KW with worm gear reduction for the drive unit, it’s easy for the rotation of 10 meter boring bar. And the hydraulic power pack with 18.5KW(25HP), it meets most of on site line boring machining.

Boring bar diameter from 30-400mm could be customized. A suitable solution can be specified according to the needs of customers.

Welcome to send your enquiry for the on site line boring machine.

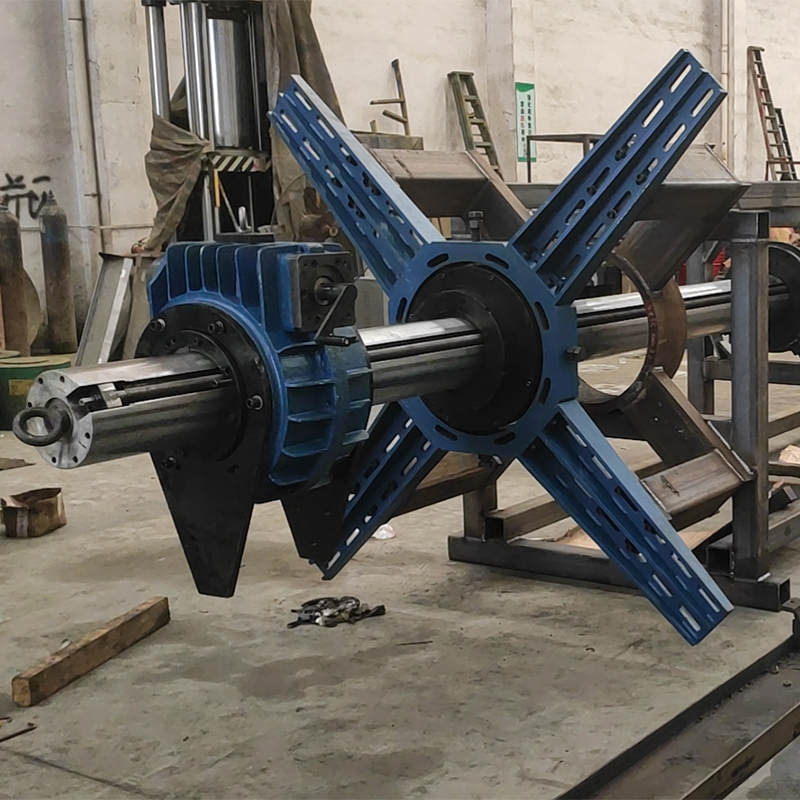

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science as well as the theory of quality the basic, have confidence in the very first and management the advanced for Hot New Products In Line Boring - LBM220 Portable Line Boring Machine – Portable Tools , The product will supply to all over the world, such as: United Kingdom, Luxemburg, Jersey, We insist on the principle of Credit being primary, Customers being the king and Quality being the , we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!