For flange repairs, in order to avoid the need for long downtime, most oil and gas companies have used on-site flange plane processing machines for processing, saving the time and effort of pulling large workpieces closer to the workshop for processing, and reducing The cost of transportation and the huge loss caused by downtime.

Some workpieces are really immobile or have limited machining space, requiring a portable on-site flange facing machine for turning or milling.

For the damage of the flange sealing surface, the cost of leakage is extremely high, and it will cause harm to the environment. If the flange cannot be sealed with a gasket, the flange needs to be repaired or replaced. The general maintenance type:

1. Remove the corroded flange and weld a new flange

2. On-site machining of sealing surfaces or RTJ sealing grooves, octagonal grooves within flange tolerances

3. On-site machining of butt welds and sealing surfaces/octagonal grooves

4. Repair flange face with polymer conforming material

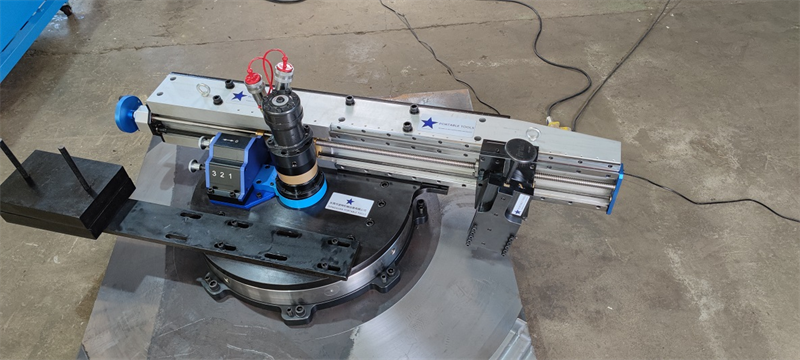

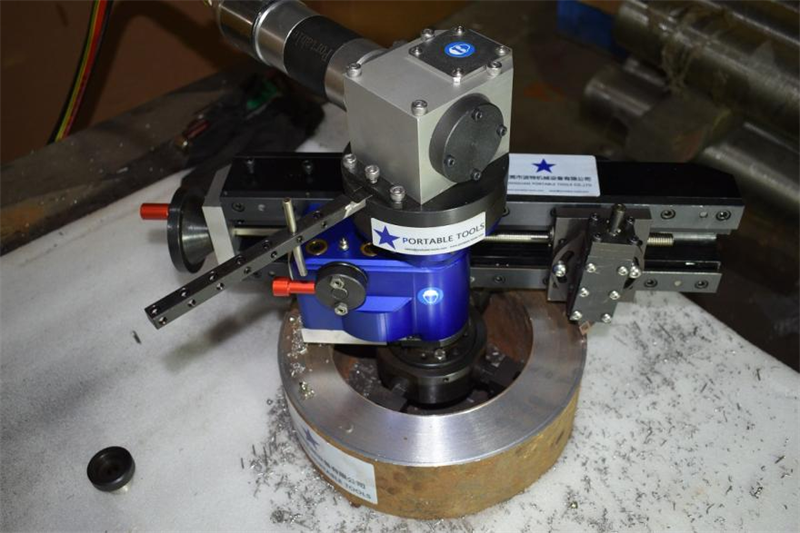

Dongguan Portable Tools Co., Ltd. has developed a portable flange plane processing machine for flange maintenance, which can process flange plane, flange water line repair, flange RTJ sealing groove processing, and octagonal groove processing. The processing range of portable flange processing equipment: 25.4-8500mm, the equipment can be customized according to the specific situation of the site.

If there is dangerous gas at the processing site, we can also provide air motors as power to avoid the generation of sparks and ensure the safety of on-site construction.

The machining accuracy of the flange sealing surface can reach RA1.6-3.2, and the equipment can also be customized according to the specific working conditions on site.