Portable keyway slot milling machine

Portable milling machine advantage compare to the heavy duty workshop milling machine

When comparing portable milling machines to heavy-duty workshop milling machines, portable models offer unique advantages that make them indispensable for specific applications, particularly for on-site or in-situ machining. As Dongguan Portable Machine Tools, a leader in on-site machine tools with two decades of experience, we’ve seen firsthand how our portable milling machines—like portable keyway milling machines, portable gantry milling machines, and portable linear milling machines—shine in scenarios where traditional workshop machines fall short. Below, I’ll break down the key advantages of portable milling machines over heavy-duty workshop milling machines, using a friendly and straightforward tone, while weaving in the required keywords and our expertise in ODM/OEM customization.

1. Portability and On-Site Flexibility

The standout advantage of portable milling machines is their ability to bring precision machining directly to the workpiece. Unlike heavy-duty workshop milling machines, which are stationary behemoths weighing thousands of pounds and requiring a fixed setup in a machine shop, our on-site milling machines are compact and lightweight. For example, our LMB300 portable keyway milling machine weighs just 78 kg and can be carried to remote job sites like shipyards, power plants, or oil refineries. This portability eliminates the need to disassemble and transport large components—like turbine casings or pump bases—to a workshop, saving days or even weeks of downtime.

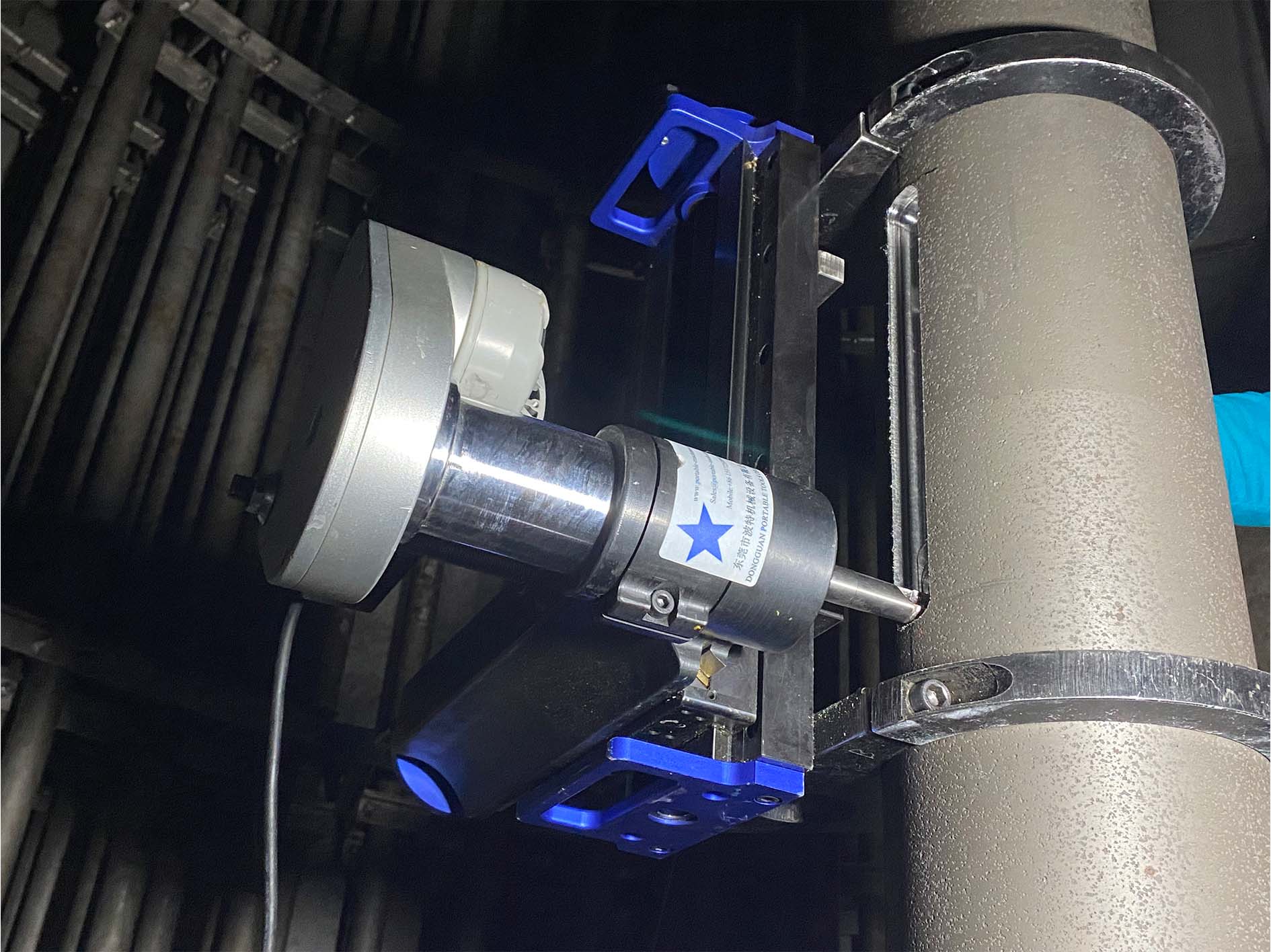

With models like the portable gantry milling machine or portable line milling machine, you can set up directly on the workpiece using magnetic bases, chain clamps, or bolting systems. This flexibility makes in-situ milling machines ideal for tasks like flange facing, heat exchanger repair, or keyway cutting on oversized equipment that can’t be moved easily.

2. Cost and Time Efficiency

Transporting large components to a workshop for machining on a heavy-duty milling machine is not only logistically challenging but also expensive. You’re looking at costs for cranes, transport vehicles, and extended downtime. In contrast, our field milling equipment, such as the portable 2-axis milling machine or portable 3-axis milling machines, allows you to perform high-precision tasks on-site, slashing labor and logistics costs. For instance, our KWM150 slot key milling machine can cut a 6-inch keyway in under four minutes, compared to hours or days when factoring in transport and setup for a workshop machine.

Additionally, portable milling machines are designed for single-operator use, reducing manpower needs. This efficiency makes them a cost-effective choice for industries like shipbuilding, mining, or power generation, where time is money.

3. Versatility for Diverse Applications

While heavy-duty workshop milling machines excel in controlled environments with large-scale, repetitive tasks, they lack the adaptability of portable milling machines. Our portable milling machines, like theGMM2000 portable gantry milling machine, can switch between linear and gantry configurations, handling tasks from surface milling to complex keyway milling. Models like the KWM150 portable keyway milling machine are perfect for cutting precise slots on shafts, while our portable linear milling machine tackles large surfaces like steel mill stands or pump pads.

Unlike workshop machines, which often require custom fixtures for each job, our in-situ milling machines come with modular mounting systems and adjustable beds, making them suitable for a wide range of workpieces. Need to mill a heat exchanger or perform bead shaver milling for weld prep? Our machines handle it all, often with customizable stroke lengths or spindle options tailored to your needs.

4. Customizability for Specific Needs

At Dongguan Portable Machine Tools, we’ve been leading the industry for two decades, and ODM/OEM are welcomed according to clients’ requests. Unlike heavy-duty workshop milling machines, which are typically standardized for high-volume production, our portable milling machine factory specializes in bespoke solutions. Whether you need a CNC milling machine with automated controls, a portable 3-axis milling machine for multi-directional cuts, or a specific bed length for a unique project, we can customize our machines to match your exact requirements. For example, we can modify the LMB300 portable linear milling machine to include a hydraulic drive or extend its X-axis stroke up to 6000mm for oversized components.

This level of customization is rarely feasible with workshop machines, which are designed for general-purpose use and lack the flexibility to adapt to unique on-site challenges. Welcome to send inquiries for your customized on-site machine tools!

5. Ease of Setup and Operation

Heavy-duty workshop milling machines require a stable power source, extensive setup time, and often a team of skilled operators to manage complex controls. In contrast, our portable milling machines are designed for quick setup and ease of use. For instance, the LMB300 portable line milling machine features a magnetic base and can be installed in minutes, even in tight spaces. Many of our models, like the portable 2-axis milling machine, offer manual or semi-automatic feeds, making them accessible to operators with varying skill levels.

For hazardous environments, such as oil and gas facilities, we offer pneumatic-powered options that ensure safety without sacrificing performance. This contrasts with workshop machines, which are typically tethered to electric power and less suited for field conditions.

6. Precision in Challenging Environments

You might think that portable milling machines compromise on precision compared to their workshop counterparts, but that’s not the case. Our keyway milling machines and CNC milling machines deliver workshop-quality results, with surface roughness as fine as Ra3.2 for finishing cuts. Features like precision ball screws, dovetail guides, and optional CNC controls ensure accuracy, even when mounted vertically or upside down on a job site. For example, our CMM304 portable CNC milling machine offers motion control for complex tasks like thread milling or stud removal, rivaling the precision of heavy-duty machines.

Moreover, our machines are built to withstand harsh environments—think dusty mines or salty shipyards—where workshop machines would struggle. Their sealed lubrication systems and robust construction ensure consistent performance, making them reliable field milling equipment.

7. Reduced Infrastructure Requirements

Heavy-duty workshop milling machines demand significant infrastructure: a dedicated workshop space, stable power supply, and often cooling systems or dust extraction. Our portable milling machines, however, are self-contained and require minimal setup. Models like the bead shaver milling machine or slot key milling machine can operate with portable power sources, such as electric or pneumatic drives, making them ideal for remote locations where workshop facilities aren’t available.

Why Choose Dongguan Portable Machine Tools?

As the leader in on-site machine tools, Dongguan Portable Machine Tools has been crafting high-quality portable milling machines for 20 years. Our expertise spans portable keyway milling machines, portable gantry milling machines, and more, all designed to deliver precision, durability, and value. Unlike heavy-duty workshop machines, our in-situ milling machines offer unmatched portability, cost savings, and customization, making them the go-to choice for on-site machining.

Our factory is a professional manufacturer of on-site machining equipment, and we’re here to help you find the perfect solution. Whether you need a standard portable linear milling machine or a fully customized CNC milling machine, we offer unbeatable value, top-notch quality, and rock-solid reliability. Contact us today to discuss your needs and let us craft your ideal field milling equipment. Welcome to send inquiries for your customized on-site machine tools!