What is portable flange facing machine and how to choose it

Different manufacturer of industries are promoting their products on website, but may clients can’t choose what they need most for their needs. Here we are to help them to understand what benefits them best and offer some guidance for the portable flange facing machine tools.

What is flange facing machine tools?

Flange facing tools is an equipment for repairing and maintenance service of flange surfaces. It helps avoid leakages and corrosion by maintenance and repair of damaged flanges on time, it makes sure the good connection joint integrity between them for the flanges with the on site service of portable flange facing machining.

Why is the flange facing machine necessary?

Flanges are producted well in the factory production shop. But the surfaces will be damaged will occur on the transportation and installation, these damages will showed in different ways, such as scratches or dents on the sealing surface. They will cause disatrous consequences if they are not repaired and maintenance or replaced be removed using a split frame/clamshell cutter in time.

How is the flange facing machine works to reduce the risk of leakages and corrosion?

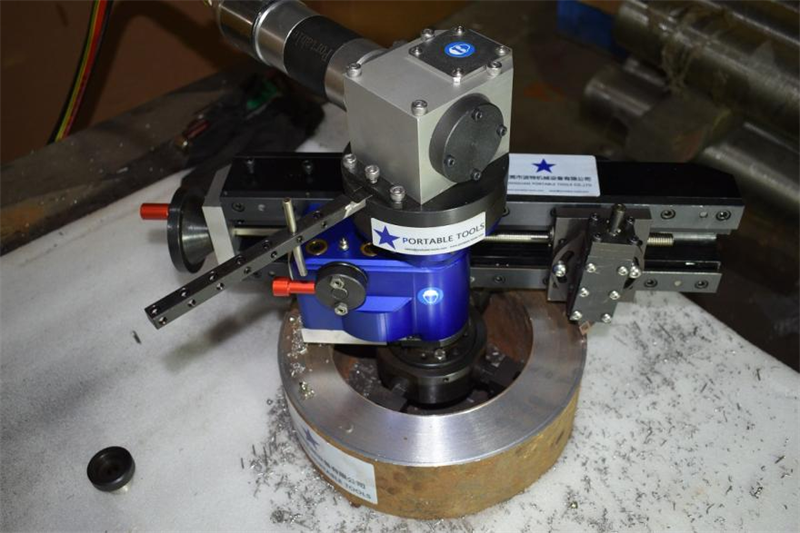

Flange facer works with the cutting tool traveling in a spiral path across the face of the flange. Flange facing cuts the flanges to give them a spiral grooved finish A flange with a spiral grooved finish is less liable to leakage, as any gas or liquid is forced to travel in the long spiral path rather than across the flange face.

What kind of industries needs flange facing machine service?

Oil and gas, refinery and value plants,petrochemical and pharmaceutical production plants, pipelines and power generation require flange facing more often than other industries.

Difference of portable flange facing machine tools and heavy-duty models in workshop?

Flange facing machines tools has different models, one for portable tools, it’s designed with light and operated easily with one single or few technicians. Another is for the heady-duty flange facing tools, they are located in the workshop usually, it works more precision and stable with heavy base plant. But the portable flange facing cutting tools are more suitable for the on site service, it eliminates logistical cost issues that go along with repairs and major replacements on any large equipment that is not easily moved, portable flange facing machining comes with high precision also with workshop.

How to choose the suitable flange facer?

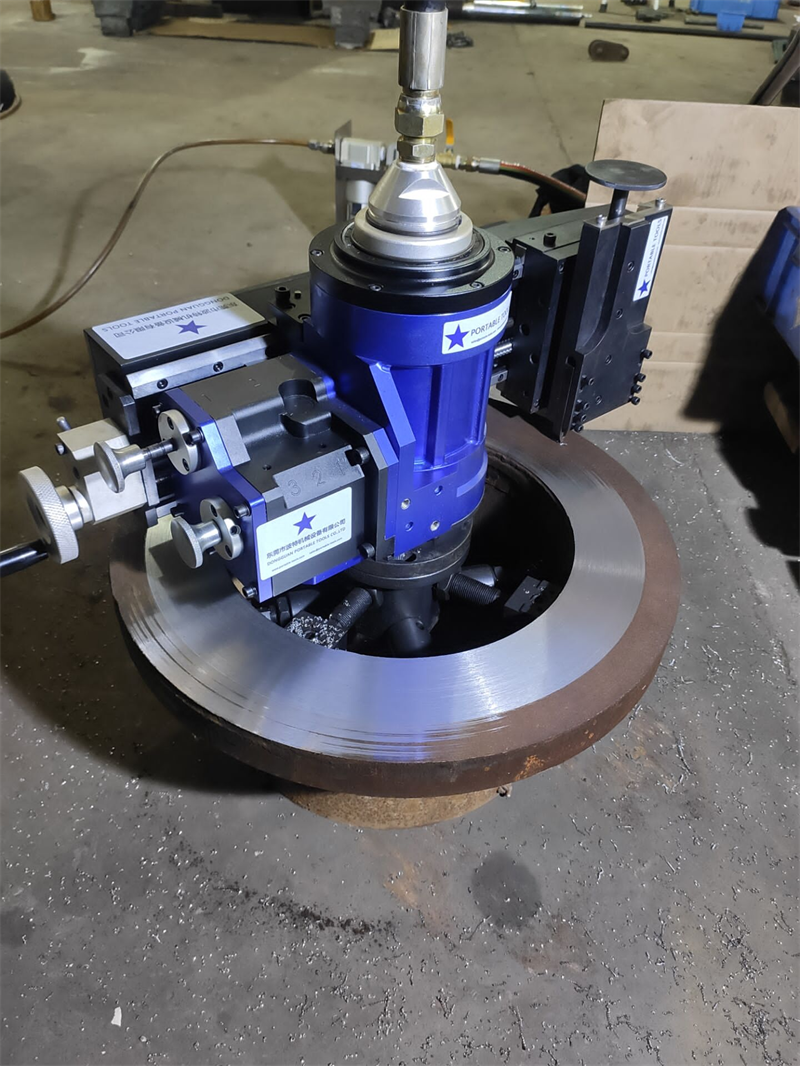

1. We have different model of flange facer, ID mounted and OD mounted flange facing machine, ID Mounted flange facing machine-clamp legs inside of the machine are placed inside the flange. OD mounted flange facing machine-clamp legs inside of the machine are placed around the flange, you need to know or tell us what’s the situation your working condition, then we can suggest you the suitable one.

2. Working diameter range, our portable flange facing machine tools working diameter from 0-6000mm, even more. We are the manufacturer of on site machine tools,ODM and OEM are welcomed for customized machine tools.

3. Power needed, we can provide pneumatic motor / servo motor / electric motor / hydraulic power pack for different flange facing cutting condition.

Pneumatic motor is light and safest power without spark, it’s the most popular power for the industries of oil and gas, refinery…

Can we choose the cheap flange facer?

Price is not the only one factors we should consider, but also the safety of flange facing repairing and cost+risk of leadages for the flange facing tools. Cheap flange facers are not robust enough, they are not stable or precision up to the job, if a machine is not stable it can move during the machining process, causing damage to the flange and producing an inconsistent surface finish. Another issue is that some machines don’t have pre-set gears. These cheaper variable feed machines can (in theory) produce a wider range of finishes, but can inconsistent and be fiddly to operate.

Inferior machines will casue consequence leakages and corrosion which leads the explosion, it’s beyond our control we can image with pre-set feed rates you will make consistent spiral groove surface finishes .

What are the Applications of Flange Facing Machine Tools?

Re-facing of main inlet steam flanges.

Repairing heat exchanger nozzle flange.

For sealing and weld prep, facing and beveling of the pipe is required.

Repairing flat face raised face and phonographic finish flanges.

Repairing piston rod mating flanges.

Boiler feed pump flanges.

Re-machining the gasket seal on tube sheets.

Cutting new grooves or repairing ring grooves.

Vessel and plate weld prep.

Re-facing ship hatch sealing surfaces.

Re-machining bearing surface of rotary cranes.

Re-surfacing large pump base housings.

Re-facing valve flanges and repairing heat exchangers.

Flange milling wind tower section

Ship thruster mount facing, drilling, and milling

Oil, Gas and Chemical

Power Generation

Heavy Equipment

Ship building & repair

Piping system flanges

Valve flanges and bonnet flanges

Heat exchangers flanges

Vessel flanges

Flange faces on piping systems

Pump housing flanges

Weld preps

Tube sheet bundles.

Bearing mounting bases

Final drive hubs

Bull gear faces

Manufacturing of mining

If you want to know more information or customized flange facing machine, please contact us sales@portable-tools.com freely.