BWM750 Auto Bore Welder Machine

Detail

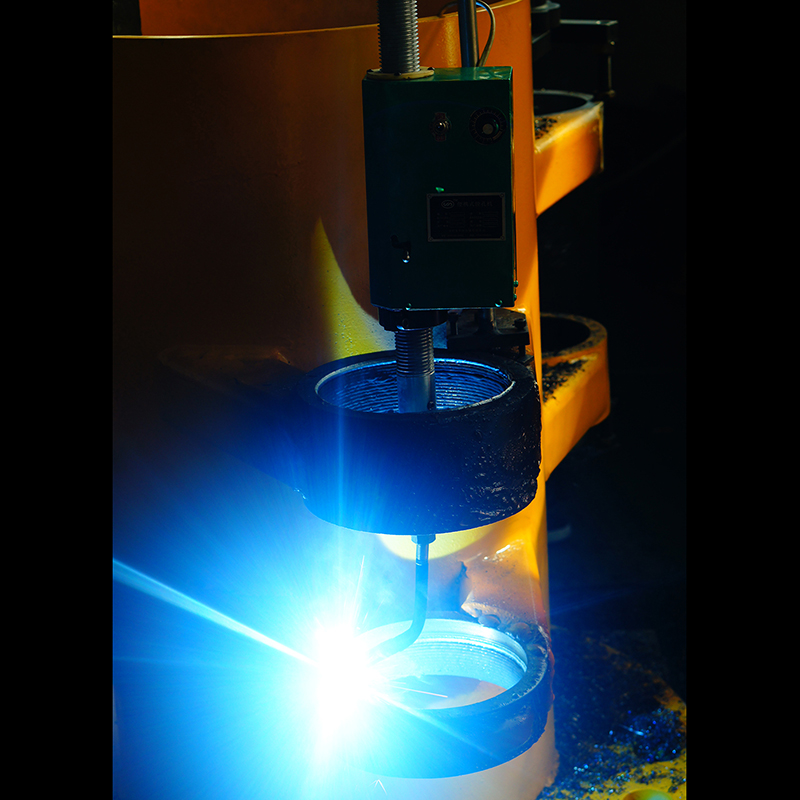

BWM750 bore welding machine match with portable line boring machine well.

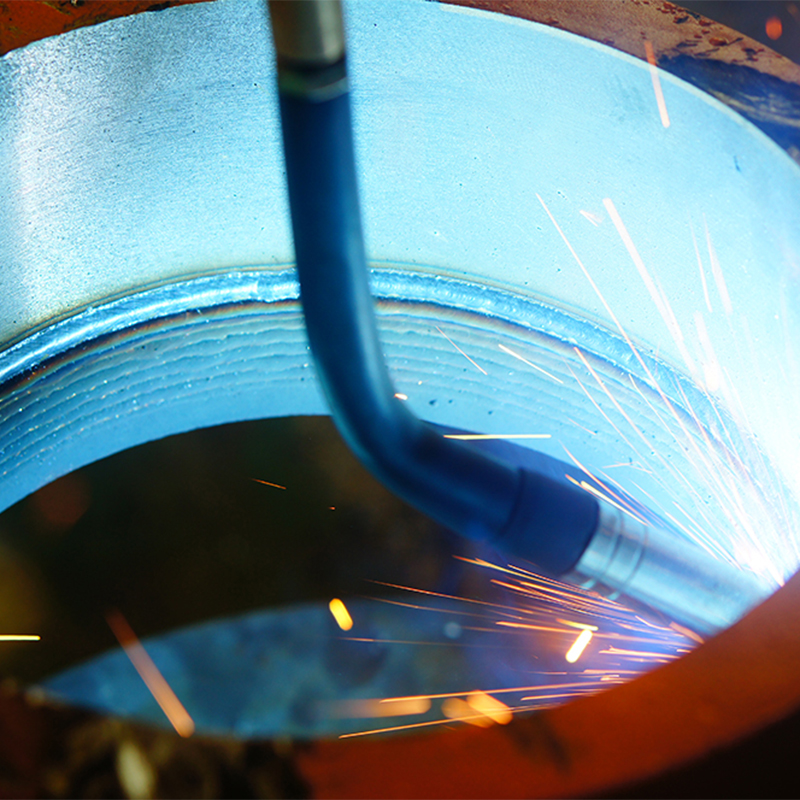

Portable auto bore welding system has 3 function: ID weld, OD weld and Face weld. ID welding diameter: 40-450mm, OD welding diameter: 20-750mm, Face welding diameter: 20-610mm. Welding stroke: 280mm

Auto Bore Welder automated step welding system will decrease dramatically while you produce precise, uniform, high-quality welds as compared to hand welding techniques.Auto bore welder machine works with MIG welding machine, Power of MIG 350W or 500 W is a good choice.

Aluminum package makes it portable and easy to carry out for on site line boring and welding machining.

Auto bore welder match with different kind of connector, including Euro, Miller,Lincoln and Panasonic.

Auto welding equipment can improve production efficiency. Bore Welding equipment has short response time and quick action than human labor. The automatic welding equipment does not stop or rest during the operation process to maximize the processing time

Auto Welding equipment can reduce costs of factory and more efficiency.

Auto welding equipment can improve product quality. During the welding process, as long as the auto bore welding parameters and motion trajectory are given, the equipment will accurately repeat this action. Auto welding parameters such as welding current, voltage, welding speed and welding dry elongation determine the welding result. When using welding equipment, the welding parameters of each weld are constant, and the quality of the weld is less affected by human factors, which reduces the requirements for workers' operating skills, so the welding quality is stable. In manual welding, the welding speed, dry elongation, etc. are all changed, so it is difficult to achieve uniformity of quality, thus ensuring the quality of our products.

Auto welding equipment can shorten the cycle of product modification and replacement and the corresponding equipment investment. It can realize the welding automation of small batch products. The biggest difference between the equipment and the special machine is that it can modify the program to adapt to the production of different workpieces. When the product is updated, it only needs to design the corresponding fixture according to the updated product, and the equipment body does not need to do anything. Changes, as long as the changes call the corresponding program commands, product updates and equipment updates can be achieved.

Adjust the current is the key to use the PWM750 auto bore welding machine. A professional of operator will cut down the set up time and make the auto welding machining nice and easy.