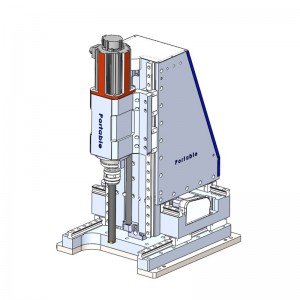

LMB6500 Linear Milling Machine

Detail

LMB6500 portable linear milling machine is the suitable portable lightweight on site milling machine. It’s designed for the on site milling project, which the heavy-duty gantry milling machine and other big milling machine has no such advantages:

1. Portability and on-site flexibility.

The standout advantage of on site portable milling machine which bring high portability machining to the project.The compact and lightweight design makes our on-site milling machine can be fixed and setup quick and easy with less operators.

LMB6500 portable line milling machine can be assembled together through modular design,fast and easy.

2. Cost and Time Efficiency

LMB6500 on site milling machine,it’s easy to carry out for remote jobs on site, like the Power plants, refineries, petrochemicals, construction machinery, ship repair, water conservancy projects, This efficiency makes them a cost-effective choice.It saves a lot of down time and cost by avoiding the time spent on disassembly, assembly, commissioning and transportation of large objects and labor cost.

Our in situ milling machine has different design, such as portable 2 axis milling machine LM1000 linear milling machine and portable 3 axis milling machine tools LMB6500 on field milling machine allows you to perform high-precision tasks on-site, slashing labor and logistics costs.

3. Versatility and flexibility

Although the heavy machinery in the workshop is quite stable and reliable, its working form is relatively simple and not suitable for various working conditions of on-site processing and maintenance services. Our LMB6500 line milling machine can adjust the direction of the milling head, the diameter of the milling cutter, the milling plane or keyway, the travel of the XYZ axis, the drive mode and the possibility of CNC in time according to the real-time situation.

- 4. Easy installation and operation

Large workshop machines require sufficient space, stable foundations buried long in advance, a lot of setup time, and stable three-phase power supply, and professional technicians are required to operate, control and debug precision mechanical equipment for a long time. In contrast, our portable milling machines are designed for quick setup and ease of use. For example, the LMB6500 portable wire milling machine only requires a few technicians to be trained for a period of time, and can be installed in a short time even in a small space.

For hazardous environments such as oil and gas facilities, we provide pneumatic drive options that ensure safety without sacrificing performance. This is very different from workshop machines, which usually rely on electricity and are not very suitable for field conditions.

5. High precision in situ machining

We use the high precision of CNC milling machine to manufacture the parts, to ensure accuracy of on site machining , our CNC milling machine comes from Japan and Germany, it has super reliable stability and high quality compares to heavy-duty milling machine in workshop.Our in in situ milling machine can make the surface roughness as fine as Ra3.2 for finishing cuts and flatness:0.05mm/meter . The single cutting depth for 2mm for fine milling. LMB6500 linear milling machine could be mounted vertically or upside down when it’s needed for multiple installation methods also.

6. Customizability for Specific Needs

Dongguan Portable Machine Tools as the leader factory of on site machine tools, we’ve been leading the industry for two decades, and ODM/OEM are welcomed according to clients’ requests. Unlike heavy-duty workshop milling machines, which are typically standardized for high-volume production, our portable milling machine factory specializes in bespoke solutions. Whether you need a CNC milling machine with automated controls, a portable 3-axis milling machine for multi-directional cuts, or a specific bed length for a unique project, we can customize our machines to match your exact requirements. For example, we can modify the LMB6500 portable linear milling machine to include a hydraulic drive or extend its X-axis stroke up to 8500mm or more for oversized components.

This level of customization is rarely feasible with workshop machines, which are designed for general-purpose use and lack the flexibility to adapt to unique on-site challenges. Welcome to send inquiries for your customized on-site machine tools!

Why Choose Dongguan Portable Machine Tools?

As the leader in on-site machine tools, Dongguan Portable Machine Tools has been crafting high-quality portable milling machines for 20 years. Our expertise spans portable keyway milling machines, portable gantry milling machines, and more, all designed to deliver precision, durability, and value. Unlike heavy-duty workshop machines, our in-situ milling machines offer unmatched portability, cost savings, and customization, making them the go-to choice for on-site machining.

Our factory is a professional manufacturer of on-site machining equipment, and we’re here to help you find the perfect solution. Whether you need a standard portable linear milling machine or a fully customized CNC milling machine, we offer unbeatable value, top-notch quality, and rock-solid reliability. Contact us today to discuss your needs and let us craft your ideal field milling equipment. Welcome to send inquiries for your customized on-site machine tools!