If you want to buy or rent the flange facing machine for your business, you need to know what the flange facing machine tools to do, what benefits the flange facing machine will get for you in the future comes.

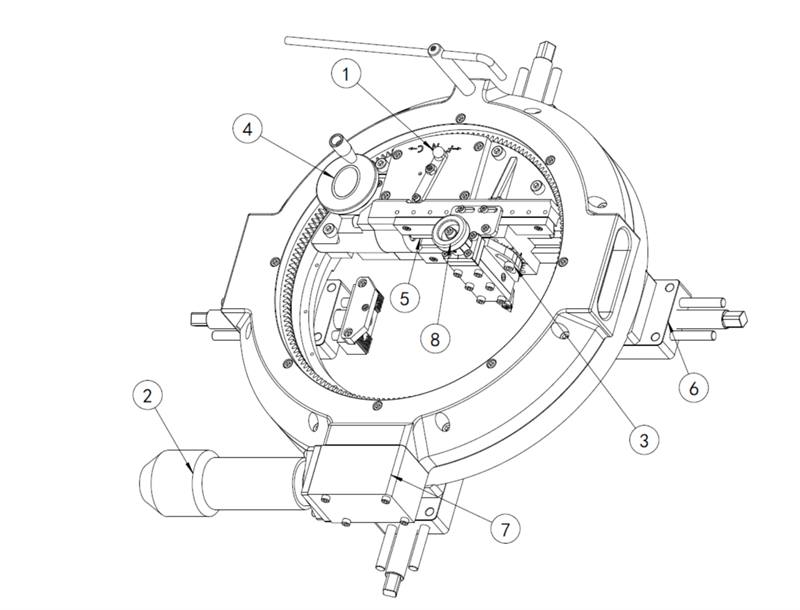

Mounted option-Portable flange facing machine get two models in total. ID mounted flange facing machine and OD mounted flange facing machine. What is the ID mounted flange facer? ID mounted flange facing tools has it’s own legs support inside the flange hole, so the flange facing machine will works on the flange . ID mounted flange facer will machine the flange face, or milling the flange ,counterbore,or RTJ cutting. ID mounted flange facing machine refacing the flange to smooth finish or stock finish with different lead screws.

Another mounted flange facing machine is OD flange facer. OD flange facing machine works around the flange, easy to operate it.

Flange facing diameter - when you choose a portable flange facing machine, what is the working range of the flange facer capable of machining? You could contact our sales manager to get more information about the specification of flange facing machine or you could share the situation of on site flange faces, so we will suggest you the best options.

Motor Power - Normally the flange facing machine has different motors with volatile situation. In the chemical plant or oil and gas industries , it belongs to dangerous with flammable and explosive gas. The spark is forbidden. So the pneumatic motor is the best option. Notice: with pneumatic model of flange facing machine, it needs a compressor big enough and longer tube to supply the air, that’s the key to work well for the on site flange facing job.

Electric motor and hydraulic power unit comes with spark, it fit for normal factory. Electric motor gets small body with small torque, so it works for the limited room and flange face. Hydraulic power pack comes with high torque, but also with heavy body, it’s about 450kg without oil.

Repeatable finish — Getting the right spiral-serrated finish should be easy for an experienced operator, but not all machines can guarantee the same number of grooves per inch on a given setting each time it is used. The good machines needs superior operator who knows it.

Mounting options — Find out how the flange facing machine mounted as your suppliers, vertically, horizontally or upside-down, that will save your cost and energy pretty much.

Warranty - what if the machine comes with problem. Will you get the support from your factory who fabricate it? Such as spare part or engineer instruction. Learn more before the purchase, such as the stock, price,lead time and warranty.

Function - Raised Face Flanges, Heat Exchanger Flanges, Techlok Flanges, Recessed Gaskets and Journals, Weld Prep, Hub Splines, RTJ Flanges, Lens Ring Joints, SPO Compact Flanges, Rotating Ring Flanges and the accessories it comes for different flange facing jobs.

Availability - If the flange facing machine in stock. How long the flange facer be fabricated? The production time, delivery time by Sea freight or air? And spare part service.

Quality - what kind of quality it is, the reliability of portable flange facing machine. You don’t want to waste your time and energy for the continuous problems that comes.