Portable Flange Facing Machines

About portable flange facing machine:

What is the portable flange facing machine?

On site Flange facing service is the process through which the machining work resurfaces the flanges. It helps to create new mating surfaces that ensure a perfect seal when you assemble it. Flange facing is done using a tool known as the flange facing tool, flange facers, or flange facing machine

For portable flange facing machine, it has different models, it gets internally mounted flange facing machine or OD External Mounted flange facing machines for all types of flange facing, seal groove machining, weld preparation and other machinings.

Dongguan Portable Tools Co.,Ltd , as a professional manufacturer of on site machines tools, we manufacture the different size of flange facers, including ID and OD flange facing machines , which covers range from 1"-236" ID flange facing machines.

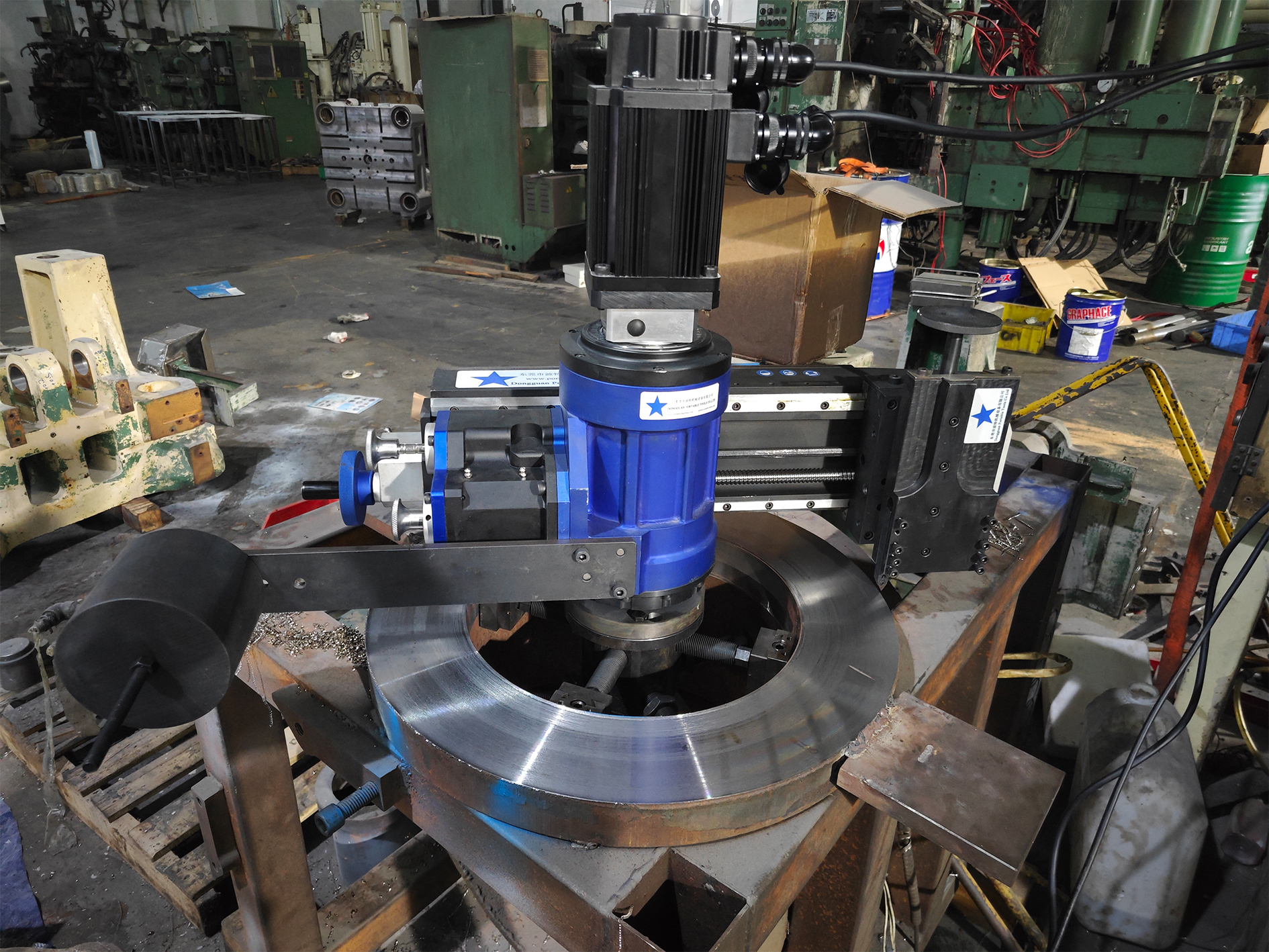

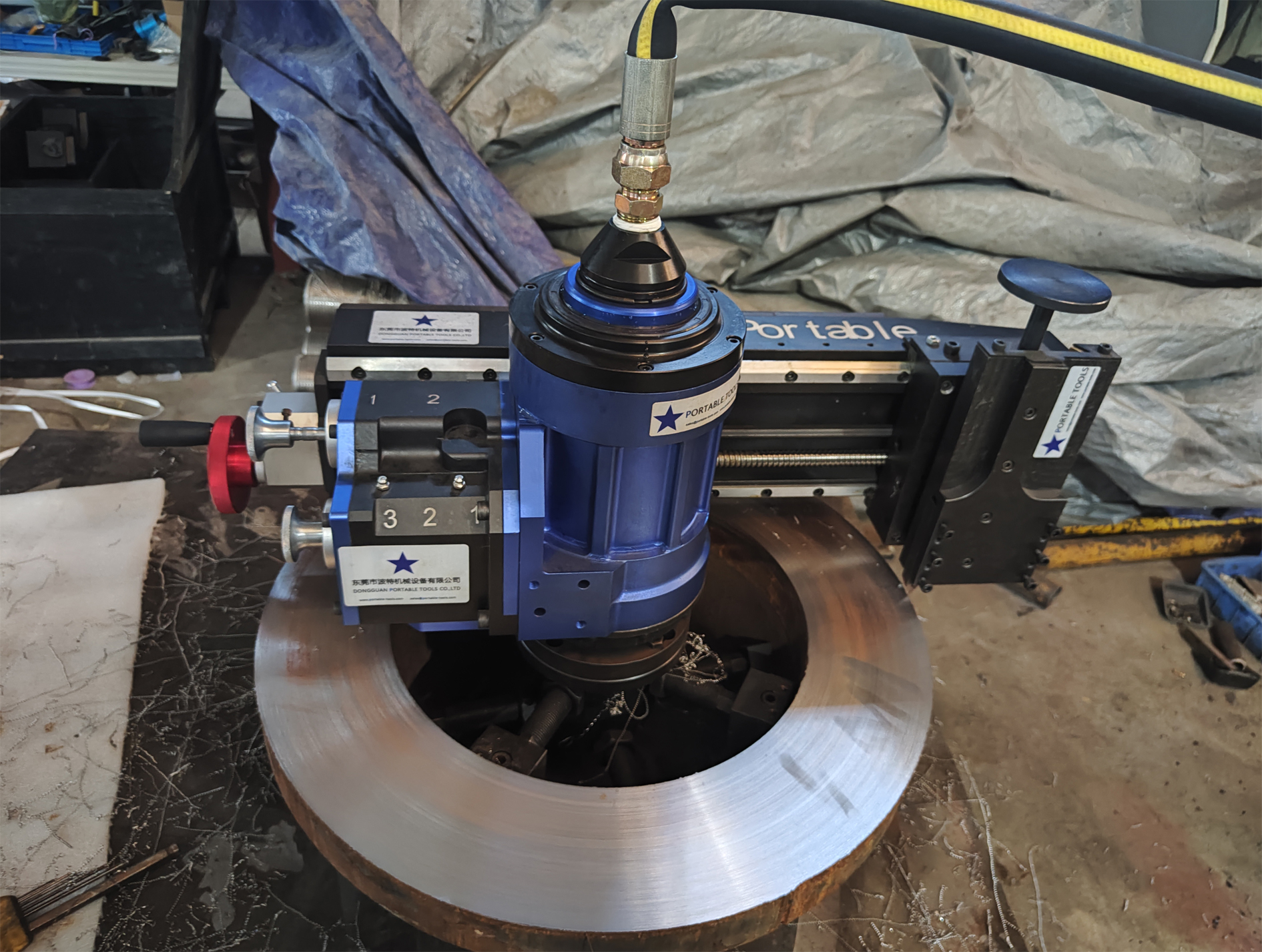

Here is the Portable ID mounted flange facing machine IFF1000 flange facing machine.

Pneumatic motor has no sparks when working, it makes sure the safety more for the working area. Pneumatic models of on site flange facing machine needs a air compressor for the power supply only.

IFF1000 on site flange facing machine has different power for it's driven options. Servo motor and pneumatic motor.

IFF1000 Flange facing machine working area: 150-1000mm

Servo motor has precision control with the pendant control box. It gets the reliable quality and easy to control for high pricise machining.

Portable flange facing machine tools are designed to recondition the flange face surface:

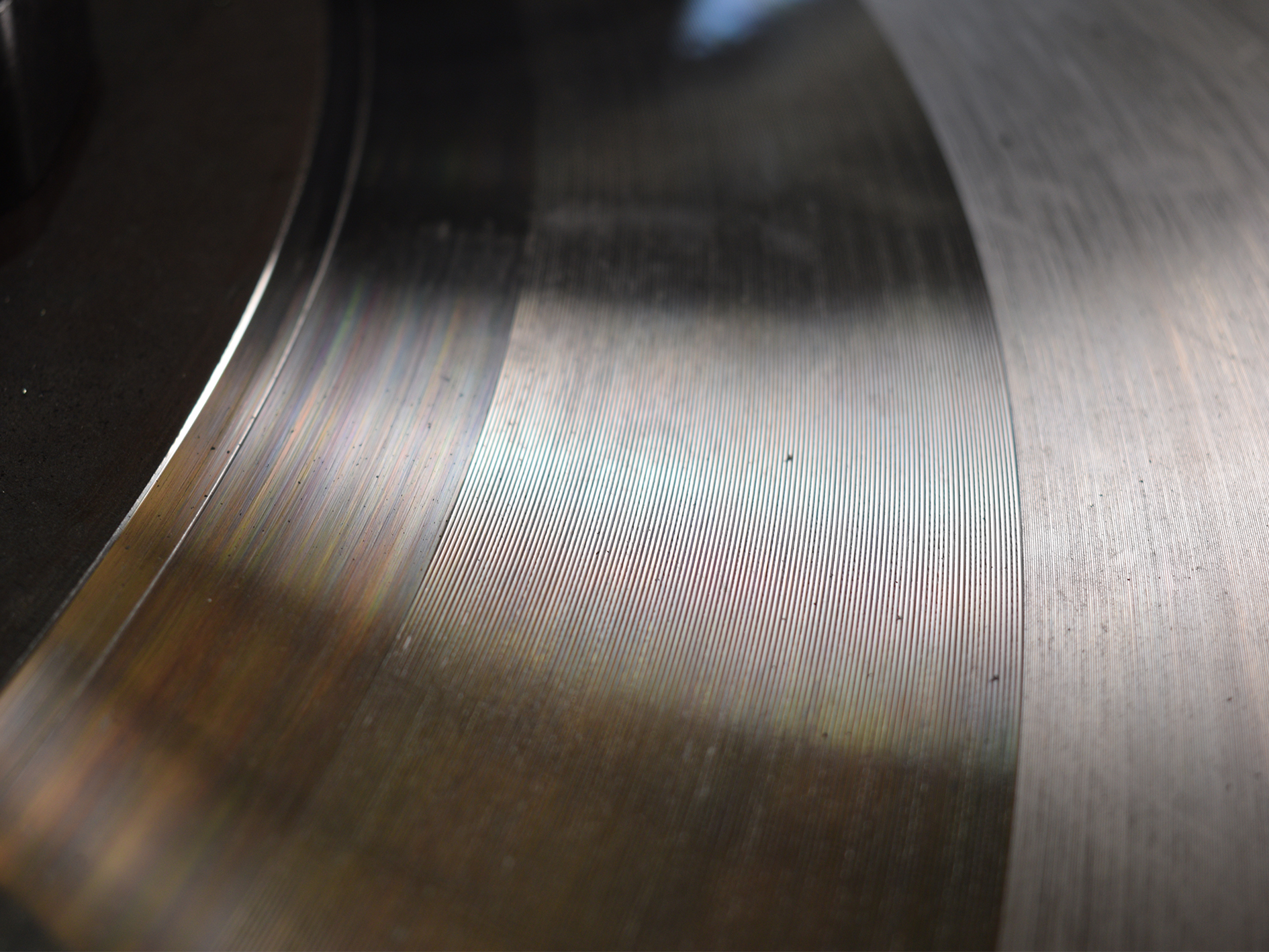

The flange face surface is the area where the sealing element (gasket) is installed. The most common flange face surface designs are smooth and serrated. Flat face (FF) flange surfaces and raised face (RF) flange surfaces require serrations if built to industry standards.

Smooth or Serrated

Flange surface faces can be classified as smooth (also called ‘flat’ or ‘plain’) or serrated. Smooth faces appear visually ‘smooth’ and have no visual tool markings. Serrated faces have some form of tool markings on the flange face.

Irrespective of which flange face surface is used, the flange assembly must be mated and tightened to the required torque in order to seal correctly.

High-temperature and high-pressure system flanges use a serrated sealing surface, or a metal gasket. Low-temperature and low-pressure system flanges may use a smooth flange face surface and soft gaskets.

IFF1000 in situ flange facing machine could machine the stock surface finish, smooth flange surface finish,continuous spiral groove (also known as ‘phonographic’)